World Exclusive! Yamaha MT-07 DT

As promised, here is the entire Yamaha MT-07 DT development-series feature, including Part III, where Yamaha and AFT pull the wraps off the company’s new-generation flat track racer – which will debut later today at Daytona International Speedway for the third-annual DAYTONA TT.

It’s rare when an Original Equipment Manufacturer builds a motorcycle or powerplant intended specifically for Grand National Championship flat track competition. In fact, it’s only happened a handful of times in the last half century.

Harley-Davidson did it in 1970 with the original XR750. Yamaha followed suit in the ’70s with its Roberts-era XS750 vertical twins and, later, its XV750 V-twin project. Honda built and raced the ultra-successful RS750 in the middle 1980s. Indian revolutionized the status quo in 2017 with its FTR750. And Milwaukee introduced its production-based XG750R as the ostensible replacement for the XR at about the same time.

History likes nothing better than to repeat itself, of course, and so it is this year with Yamaha’s new MT-07 DT factory flat track racer, which will hit the track in anger for the first time at the Daytona TT on March 14, 2019 under the Estenson Racing banner and carrying riders JD Beach, Jake Johnson and Kolby Carlile.

Like Yamaha’s previous factory-backed dirt track efforts, the successful one supporting Kenny Roberts on XS750s in the ’70s and the ill-fated venture featuring Mike Kidd and Jimmy Filice on XV750s in the early ’80s, the DT project is much more skunk works than corporate.

“Yamaha has a storied history in American dirt track racing,” says Yamaha Racing boss Keith McCarty, who began his career at Yamaha as a race mechanic 42 years ago, “and for many years the race team was quite successful. Until the FZ-07 [now called the MT-07] appeared we didn’t really have a production engine that could compete in the modern AFT Twins class. But with the FZ’s debut we suddenly did – and that got me thinking about a racing machine that was a bit different than what was being built and raced in the AFT national series.”

Coincidently, Yamaha motorcycle product line manager Derek Brooks, a former flat tracker himself, was thinking along similar lines. “When I saw the original FZ-07 production concept bike in Japan with its cross-plane parallel twin 690cc engine,” Brooks says, “my mind immediately went to building a flat tracker. While brainstorming ideas for building excitement around the Yamaha brand at that year’s AIMExpo, I figured this would be an ideal concept bike to showcase the brand as well as the relatively new FZ-07. We then went to work with noted designer, fabricator and stylist Jeff Palhegyi to build the bike.”

The DT concept blended new (FZ/MT-07) and more classic (early YZ motocrosser) shapes into a thoroughly sexy package and was an immediate hit in its Roberts-era yellow and black livery. This was especially so with the custom street-tracker crowd that’d been clamoring for decades for a production-based flat track motorcycle that could be bought at a dealership (which they saw in this prototype), but also from flat track fans wanting Yamaha to revisit its Roberts-era glory days.

“My big push to Palhegyi,” remembers Brooks, “was that I didn’t want it looking like a traditional flat tracker. The body and frame had to look like a race bike designed in 2015.”

In its traditional yellow-and-black livery, Yamaha's 2015 DT-07 Concept 'Tracker was a huge hit, and set the stage for the MT-07 DT race bike.

As exciting and well-received as it was, the DT concept was still just the first step – and McCarty wanted to take it farther than just a concept bike. It looked right and generated the sort of emotional connection the project would need from Yamaha brass and the flat track community (if it were produced on a limited basis and sold to race teams, as McCarty envisioned), and from potential buyers (if Yamaha actually built a for-sale street-legal version). But its guts – the chassis especially – were far from proven.

To determine if the frame design, geometry, suspension setup and other forward-looking technical bits designed into the DT concept bike were as functional and advantageous on an actual dirt race track as McCarty and his blue-shirted engineers thought they might be, the next step was real testing – which meant the concept prototype would have to be morphed into a running and functioning test mule. Which it quickly was.

All along, McCarty’s idea was to go beyond the dirt track status quo by doing certain things differently, and by taking advantage of his vast experience managing Yamaha’s world-class factory roadracing and motocross efforts over the years.

“The DT-07 concept bike was always much more than a styling exercise,” McCarty says. “We’d used and developed some really smart and workable designs and technology through our racing programs, and I wanted to bring some of that to our flat track effort. Things like a linkage rear suspension, the adjustable swingarm pivot, the pivot/countershaft relationship, adjustable front-end geometry, variable-length intake runners, airbox design, electronic shifting, full data-acquisition capability, improved ergonomics, the use of certain production parts, a no-fuss battery system, etc.”

With all that in mind, McCarty and Company began turning the non-running DT prototype into a running test mule, and then began assembling a second machine with spare parts – and help from fabricator extraordinaire Bryce Eikelberger – to expand their testing and evaluation footprint. The first step was to install in-house-modified, race-prepped FZ-07-spec engines that had already met the team’s target performance profile in 700 and 750cc displacements (the concept bike had a stock engine). Rick Hobbs assembled the engines, while Jim Roach managed dyno development and ECU mapping.

Controlling these powerplants were proprietary ECU and wiring-harness assemblies with specially developed mapping for the DT. Both engines made competitive power, but as always in dirt track competition, getting it to the ground smoothly and effectively through a narrow and limited-grip spec tire is the trick, and having both engines on hand throughout the evaluation process would be helpful.

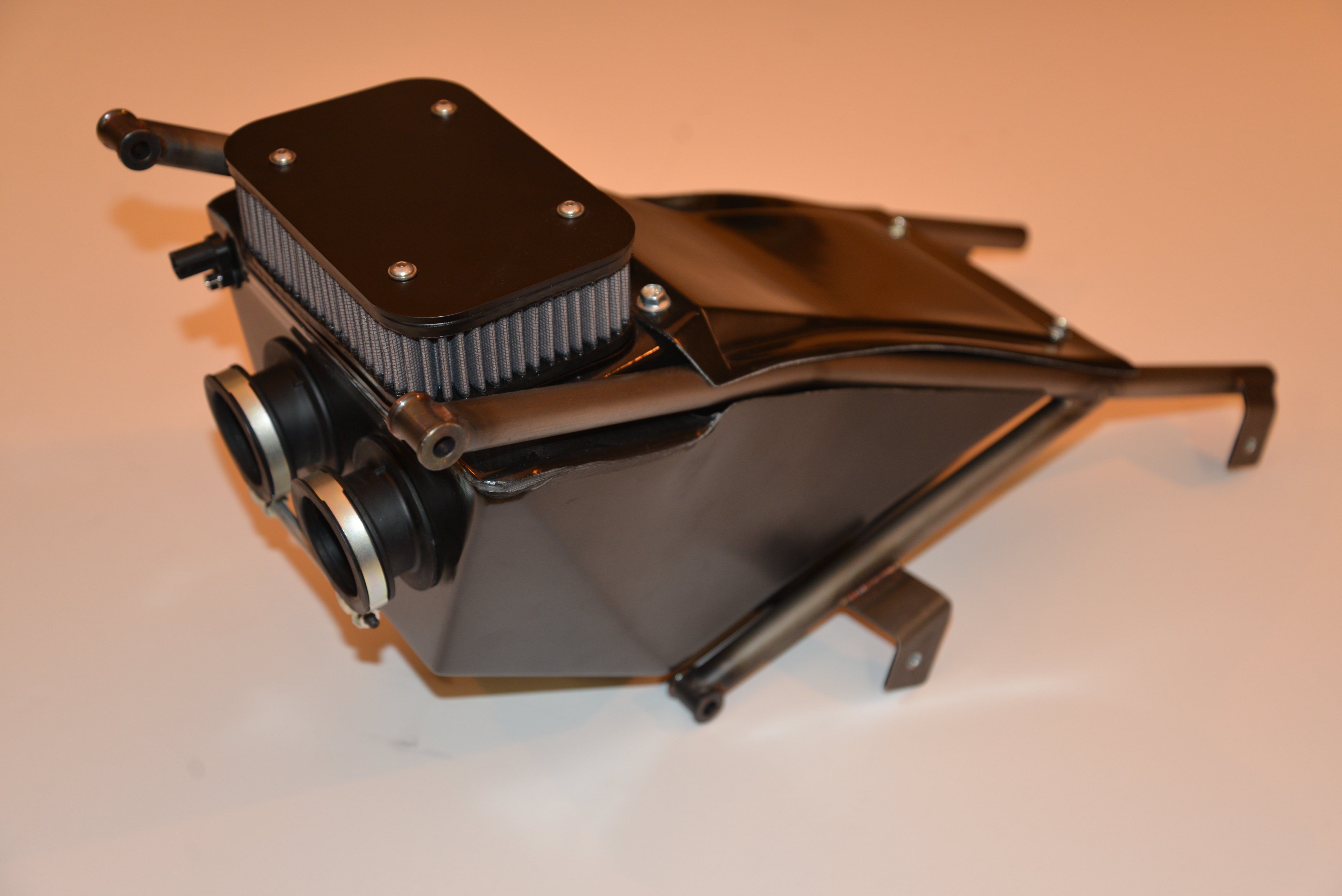

Exhaust was fairly straightforward, a ti/stainless Graves Motorsports two-into-one down pipe that tucked tightly against the engine and swingarm. The DT’s intake system, however, was significantly more involved, incorporating a custom-made carbon fiber airbox nestled behind the cylinder bank that provided enough internal room for several different velocity stack lengths, which would allow crew members to tune the power delivery for longer or shorter tracks. Typically, shorter stacks push power toward higher rpm, while longer ones generate more midrange. The breathing system is clean and helps narrow the bike’s mid-section considerably, and is a far cry from the traditional dual-K&Ns-sticking-out-the-side setup.

A key component of the MT-07 DT project is the frame, a chrome-moly steel-tube trellis assembly that surrounds the engine, eschews traditional downtubes, incorporates a large-diameter, adjustable steering stem and linkage rear suspension system, and leaves room for the all-important airbox, which allows power delivery to be tailored to the racetrack in question. The conventional fork tubes are from an older YZF-R6 and feature internals and settings from Durelle Racing. The radiator and cooling fan come directly from the FZ/MT-07 streetbike and worked superbly during development, even in 100-degree temps.

Chassis-wise, much of the good stuff McCarty envisioned was already there, baked into the design by he, Brooks and Palhegyi during initial brainstorming, sketching and fabrication. Wheelbase length, rake and trail numbers, and linkage ratios, for example, had been worked out months in advance. The chrome-moly steel tube lattice frame was rigid, left room for the airbox assembly and provided both swingarm-pivot and front-end adjustability, the latter via a large-diameter steering-stem pipe. It was light, too, which helped the entire bike be light, which allowed weight to be designed in and utilized where the chassis needed to be robust.

“We didn’t want to just add weight later to be above the minimum,” McCarty says. “We wanted the weight where it needed to be in the first place, for strength and durability, all while trying to keep the 50-50 weight balance we wanted.”

Here’s the linkage suspension system tucked away beneath the swingarm. Based on the design used on Yamaha’s championship-winning road racing machines, it allows engineers to determine and modify the progressiveness or flatness of the system’s resistance curve. A fully adjustable Ohlins shock with high- and low-speed compression and rebound damping controls the rear wheel’s movements.

For high-end suspension help McCarty turned to Chris Lessing, a long-time road race team member well-versed in the suspension design and program they’d used with the DT. “Chris knows suspension tech inside and out,” McCarty says, “and he was a big help along the way as we developed and de-bugged the system on the DT.”

Initial dynamic testing, which took place on Perris Raceway’s short track in Southern California, was the usual mix of good and bad. But despite some linkage friction issues, the bike’s performance raised eyebrows and generated excitement for the crew, which saw tons of upside.

“We ran both bikes, the 700 and the 750,” McCarty says, “and overall it went well. We learned a lot and made progress all day long. The takeaways were big for us. First off, the 750 didn’t feel like a typical 750; it felt small and light, just like the 700 did, really, and the riders loved that, along with the narrow chassis and ergonomics.

A hand-made carbon-fiber airbox assembly fits snugly within the subframe and utilizes a custom K&N filter and variable-length velocity stacks within to provide intake oxygen and tailor power delivery for the racetrack in question. Longer stacks tend to provide more midrange and would be used on TT and Short Track venues, while shorter ones typically emphasize higher-rpm power and would be helpful on Half-Mile and, particularly, Mile circuits.

“Also, the bike made smooth, easy-to-use power, and plenty of it. The riders loved that, too. In fact, our fast rider did laps that matched the fastest-ever time on that particular track, posted by John Kocinski on his dirt tracker. I was skeptical, so I called John to find out, and sure enough, we’d matched it. That didn’t mean we were ready to go out and beat Jared Mees, but it did tell us we had a good package and were in the ballpark. I was like, ‘hey, we’re on the right track!’ It definitely fueled our fire.”

Another road racing refugee is the DT’s electronic shifter system, which allows riders to ignore the clutch and just bang away at the lever, which saves a tiny bit of time on each gear change. Those foot controls, by the way, are stock Yamaha pieces, which McCarty used in the beginning since they’re functional and widely available.

A couple more tests followed, a second on the Perris Raceway short track a third on the nearby Perris Auto Speedway Half-Mile circuit, site of the 2017 AFT Finale. With the linkage and friction/stiction issues solved and suspension and ECU settings now closer to ideal, things improved even more, the goodness of the initial design becoming more evident with every lap. John Kocinski even helped out with testing, and despite not having ridden in a few years, the Hall of Famer lapped very quickly and helped dial in the bike and refine things even more.

PART III

A final shakedown run on the Perris Half-Mile occurred in 2018 with Yamaha road race champion – and now full-time AFT phenom – JD Beach, who McCarty has worked with for years. The bike, which now had a few tests under its belt along with some tweaking and fettling by Yamaha crew chief Jim Roach and his techs from the Yamaha race shop, was performing really well, and Beach went seriously fast on it.

“JD is a world-class racer,” McCarty says, “but he’s also a superb development rider, and not every great racer can say that. He’s got great feel for what’s going on and what needs to be done, and while he can ride around problems, which a great racer needs to be able to do, he can also identify things the crew needs to know. It’s so good to have him involved. He’s been exposed to the factory Yamaha road race team, and how good it is. He’s been there, been exposed to greatness, and that will be a big help going forward.

“At Perris I had the lap times from the AFT National there in late 2017,” McCarty adds, “and JD equaled winner Jared Mees’ best laps. JD did well at that National event, qualifying second and finishing third in the Main on the Team 95/G&G Yamaha FZ-07 behind Jeffrey Carver Jr. and Mees, so he knows that track pretty well. But to run those laps on what was basically an all-new design with a lot of new chassis elements in only its fourth test, well, that says a lot. It was a huge step for us. We proved that our ideas and theories about the new bike were on target, and we knew for sure we had serious upside going forward. That gives us lots of confidence, and it should bode well for the Estenson Racing guys.”

Even before the 2019 AFT season lights off at Daytona on March 14, the DT project has been a fruitful one for Yamaha. Yamaha racing fans are more jacked than they’ve been in decades about the prospect of watching these new Yamahas compete with the Indians, Kawasakis, Harleys and privateer Yamahas as JD, Jake and Colby work to gain podiums. For those fans it’s all about those ‘time-machine’ moments – ones that that harken back to yellow-and-black-leathered Kenny Roberts ripping around sideways on the XS-based vertical twins, or involve images of him ricocheting off hay bales on the TZ miler at Indy back in ’75.

Yamaha streetbike fans (and streetbike fans in general) are drooling uncontrollably, as well, thinking about the possibility of a street-legal DT-styled machine, which has been rumored. DT co-designer Jeff Palhagyi helped stoke the fires by building a street-legal version for his own garage a couple of years ago, and then letting Cycle World ride and write about it for untold thousands to read about.

In the end, though, this is really all about Yamaha being back. Being involved in professional dirt track racing again and being competitive with a new motorcycle, a new team, and a new rider – JD Beach – who, like Roberts, is championship-caliber on both dirt and asphalt. Having Beach as an AFT full-timer on factory Yamaha machinery against established American brands Harley-Davidson and Indian Motorcycle in 2019 is can’t-miss compelling, and however it all works out this season, the images that’ll be generated – and the Roberts-esque memories they’ll evoke – will resonate with fans new and old in a major way.

“We want to support American Flat Track, Estenson Racing and the sport in general,” says McCarty. “We want to succeed as a company and offer highly competitive motorcycles to riders and teams, which we think we’ve done here. It helps keep the racing exciting, it gives back to a sport that millions hold near and dear, and it helps keep Yamaha in the limelight. If we can do that we’re doing our jobs – and we’ll probably have a helluva lot of fun in the process!”

Savvy design and meticulous attention-to-detail are everywhere here, from the beautifully braced chrome-moly swingarm to the exquisitely machined alloy wheel, brake carrier and sprocket pieces. De rigueur 17-inch wheels front and rear carry Dunlop DT3 rubber.

Since it’s powered by the FZ/MT-07 street bike engine, the DT has flexibility in terms of its throttle-body size per AFT rules. Yamaha experimented with both 38 and 40mm units during development and says Estenson Racing will likely end up using both during 2019 depending on the type of racetrack in question and the power-delivery characteristics required.

Latest news

10 Minutes + 2 Laps with Tim Estenson